By Viswanath Sundharavadivel

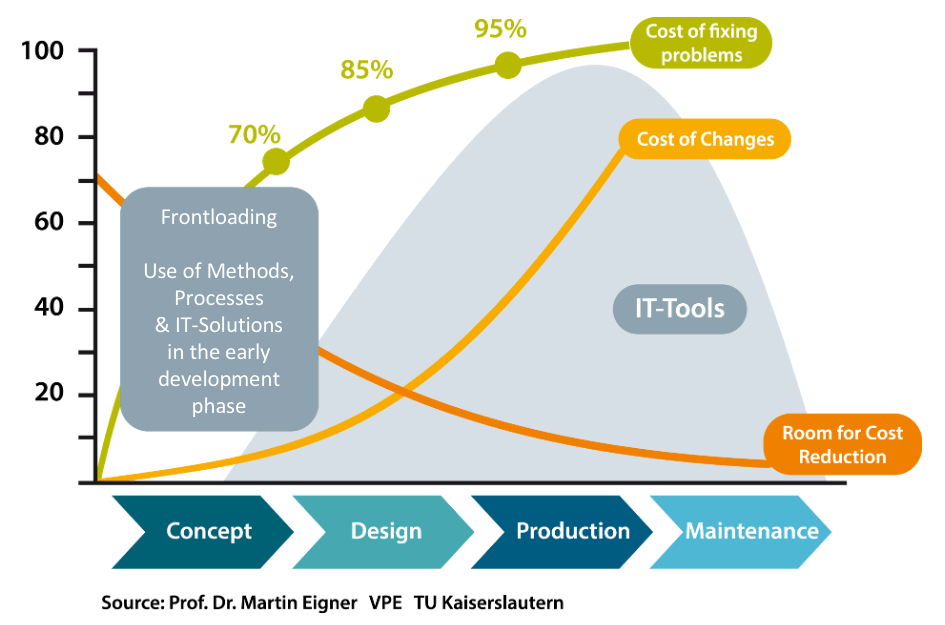

Did you know that 70% of product failures occur because of design flaws discovered too late in the development process? (Thomke, 2003). This startling statistic underscores the importance of integrating simulation tools at the onset of the design process. Among these tools, Simcenter FLOEFD stands out as a leading computational fluid dynamics (CFD) simulation software that empowers engineers to front-load CFD analysis. By providing invaluable insights and optimizing designs right from the start, Simcenter FLOEFD modernizes the design process.

Traditional approaches often relegate CFD usage to the final stages of prototype testing, leading to missed milestones and prolonged development cycles. Front-loading simulation, championed by Prof. Martin Eigner, supports the early integration of simulation tools, including CFD, into the design process.

In this article, we will delve into how front-loading simulation with Simcenter FLOEFD transforms the design process and explore strategies to encourage its adoption.

Understanding Front-Loading Simulation with Simcenter FLOEFD

Simcenter FLOEFD emerges as a standout among CFD simulation tools as it seamlessly integrates into CAD environments like Solid Edge, NX, CATIA V5, and Creo. This integration grants engineers the ability to conduct fluid flow and heat transfer simulations accurately and effortlessly within their familiar design environment. By embracing front-loading simulation, engineers gain early insights into product behavior, can spot potential issues, and make informed design decisions right from the project’s outset.

Source: The CAE simulation process (Sabeur, 2015)

The synergy between Simcenter FLOEFD and other design optimization tools, such as HEEDS, further enhances the design process. This collaboration enables automated product development processes, allowing engineers to explore a myriad of design alternatives while considering critical factors like thermal performance, structural integrity, and acoustics. As a result, the design cycle is streamlined, iterations are reduced, and products reach peak performance in less time.

Frontloading CFD has transformed the design process by allowing engineers to evaluate performance early, iterate quickly, and innovate efficiently. Unlike the validation stage, which prioritizes thorough verification, speed becomes essential during the design phase. Engineers must simulate early and frequently to keep pace with design changes, swiftly rejecting less viable ideas and identifying optimal solutions.

For designers, CFD is indispensable for simulation-driven design. It ensures seamless integration with CAD, eliminates the need for data export and model cleanup, and leverages intelligent automation for faster and more accurate analysis. Simulation-driven, designer-friendly CFD solutions effectively manage turbulence models, automatically reflect flow conditions, utilize fully automated meshing methods, and provide fast results to enable fast decision-making throughout the design process.

Benefits of Frontloading CAD-Embedded CFD:

- Better Match to Product Requirements: Integrating CAD-embedded CFD early in the design process allows engineers to tailor designs more closely to product requirements, such as achieving lower weight or faster speed.

- Reduce Downstream Development Delays and Costs: Early simulation significantly reduces downstream testing, prototyping, and change orders.

- Satisfy Customer Contractual Obligations or Regulatory Requirements: Frontloading CFD ensures that products meet customer and regulatory standards early in the design phase, mitigating compliance risk and potential delays.

- Reduce Product Lifecycle Costs: Simulation-driven design identifies optimization opportunities early, leading to lower maintenance, operational, and lifecycle costs over the product’s lifespan.

- Drive Lower Production Costs: By optimizing designs upfront, CAD-embedded CFD helps reduce production costs, improving overall profitability.

- Get Products to Market Faster: Early simulation accelerates the design cycle, enabling engineers to evaluate multiple design alternatives quickly and confidently.

Overall, the integration of CAD-embedded CFD offers multiple benefits. By leveraging simulation-driven design, companies can optimize designs, mitigate risks, and deliver superior products to market faster.

Strategies for Encouraging Adoption:

Companies can help the adoption of front-loading simulation by applying the following strategies:

- Train and Educate: Provide training on simulation tools and methods to familiarize engineers with the benefits and practical aspects of early simulation.

- Integrate with Design Workflows: Integrate simulation into the design process, so that engineers can access simulation tools directly within their CAD environment.

- Champion Success Stories: Highlight success stories where front-loading simulation led to significant improvements in product performance, cost savings, or time-to-market.

- Collaborate and Support: Foster collaboration between design, simulation, and testing teams. Encourage open communication and knowledge sharing.

- Recognize and Incentivize: Recognize engineers who use simulation early in the design cycle and offer incentives such as bonuses or awards for successful implementation.

Conclusion

Front-loading simulation with Simcenter FLOEFD empowers engineers to optimize designs, mitigate risks, and drive innovation from the outset of the design process. By embracing simulation-driven design, companies can enhance efficiency, quality, and competitiveness. Encouraging the adoption of front-loading simulation requires a concerted effort, but the rewards in terms of improved product performance, reduced time-to-market, and cost savings make it a worthwhile effort. As companies continue to prioritize innovation and agility, front-loading simulation will certainly play a pivotal role in shaping the future of engineering design.

Tata Technologies and Siemens Digital Industries Software

Identify product failure earlier in the design-cycle with front-load CFD. Talk to our Tata Technologies simulation software experts. We have been a Siemens Digital Industries Software Platinum-level Reseller for more than 25 years. Ask us the tough product development and simulation questions and we will answer with practical solutions. To connect with us to further discuss your simulation challenges, click here.

Reference

Thomke, S. (2003). Experimentation Matters: Unlocking the Potential of New Technologies for Innovation. Harvard Business School Press. Page 63.

Eigner, M., Roubanov, D., & Zafirov, R. (2017). Model-Based Systems Engineering with SysML: Managing Complexity with Innovation and Integration. Springer.

Leave a Reply